END‑TO‑END SOLUTIONS FOR THE PRODUCTION LINE

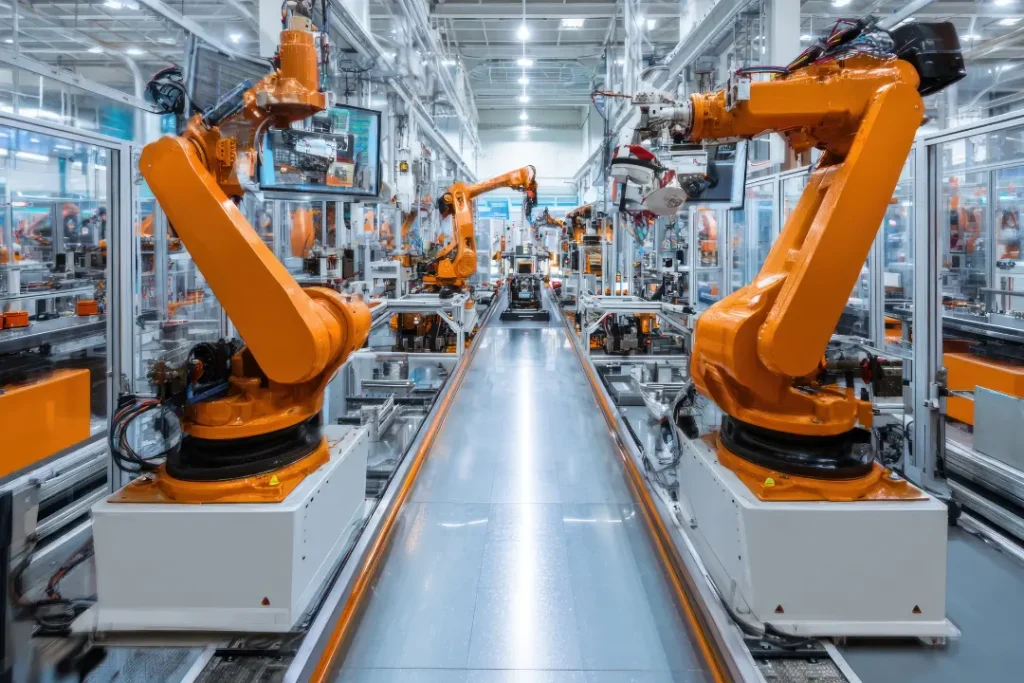

Robots, heavy machinery and people share the same plant. Risks are many: sparks in welding, vapours in painting, repetitive movements in assembly, fatigue in internal logistics. All in a 24/7 operation with zero room for error.

That’s why we design solutions that protect workers without slowing production.

Our approach combines ergonomic technical workwear, specialised PPE, industrial‑ergonomics improvements and safe lockout systems. Everything integrated with the sector’s Lean and TPM culture so safety and productivity advance together.

TECHNOLOGY AND ERGONOMICS APPLIED TO AUTOMOTIVE

Each area has its own requirements: stamping, painting, welding, assembly, internal logistics.

We adapt our solutions to every process and environment: ergonomic technical workwear, specialised PPE, exoskeletons and ergonomic solutions; machine lockout/tagout systems with LOTO and industrial signage; and digital garment management with traceability, flexible rental and tools like MyRenting360.

Our experience allows us to co‑develop solutions with operators and plant managers, testing them in real conditions and aligning them with the strictest standards, including ISO/TS 16949 and sectoral norms.

Leading OEMs and tier suppliers already rely on us to implement solutions that improve safety without slowing productivity.